Aramid Packing

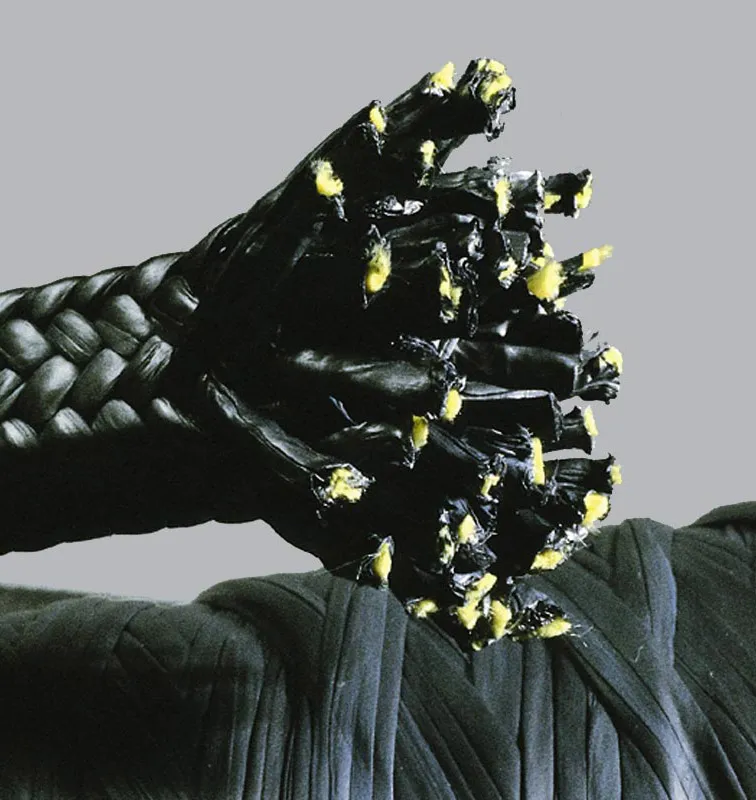

Aramid packing is braided from premium aramid fibers impregnated with PTFE dispersion and high-performance lubricants. The material offers excellent chemical resistance, high elasticity, and minimal cold flow. Known as “synthetic metallic fiber,” aramid provides a tensile strength three times that of steel while weighing only one-fifth as much. This combination of strength and low weight allows aramid packing to withstand abrasive particles, high temperatures, and high shaft speeds.

It can be used independently or in combination with other packings and serves as a reliable asbestos-free sealing solution for pump systems.

- Spool With or Not

- Custom Label & Disk

- Package Carton Box|Wooden Pallet

- Types Square |Ladder|Rectangular

Key Features

High Strength & Superior Wear Resistance

Aramid fibers deliver extremely high tensile strength and outstanding abrasion resistance, making them ideal for high-speed equipment and media containing solid particles.

Excellent Chemical Resistance

Resistant to acids, alkalis, and most chemical fluids, suitable for sealing a wide range of corrosive media.

Low Friction & Shaft-Friendly

PTFE or graphite lubrication ensures low friction, smoother operation, and minimized wear on shafts and sleeves.

Dense Structure & Reliable Sealing

Tightly braided construction with excellent compressibility and recovery provides dependable leakage control and long-term sealing stability.

Industry

Application

- Pumps

- Valves

- Rotating machinery

- Chemical

- Petroleum

- Pharmaceutical

- Food & Sugar Processing

- Pulp & Paper

- Power Generation

Material Advantages

- Extends shaft life and protects from packing extrusion at the back of the gland.

- Abrasive resistant, chemical resistant, and extrusion resistant compression packing.

- Combines tensile and abrasive resistance of Aramid, and the lubricity and heat dispersion capability of CPL fiber

Specifications

Property | Value/Range |

Temperature Range | –200°C to +350°C |

Pressure Resistance | Up to 30 MPa |

Chemical Resistance | pH 1–14 |

Color | Yellow |

Linear Speed | 3000 fpm/15 m/s |

Pressure | 1.Valve:1100Psi/150Bar/15Mpa 2.RotatingPump:300Psi /80Bar/8Mpa3.Reciprocating:2100Psi/50Bar/5Mpa

|

Material | 1.Aramid Fiber Yarns 2.lmpregnated With PTFE |

Construction | Lattice Braid From Steeger

|

Composition | Aramid Fiber and CPL Graphite/PTFE yarn

|

Lubricant | high-performance |

Speeds

| 1900 fpm |

Suitable Media

Ideal for abrasive fluids containing solid particles. Recommended for:

- Superheated steam

- Solvents

- Liquefied gas

- Syrups

- Other aggressive or abrasive fluids

Type

Braided from pure PTFE-yarn (body of the packing), and Aramid fibers (corners), impregnated with PTFE-dispersion and silicone oil

Diagonally braided from continuous Aramid fibres, impregnated with PTFE and high temperature silicone oil

Diagonally braided from gPTFE-yarn (PTFE with incorporated graphite), reinforced at the corners with continuous Aramid yarn, lubricated with silicone oil

Braided from DuPont NOMEX yarn, impregnated with PTFE and mineral oil

Diagonally braided from high-grade aramid staple-fibre-yarn, impregnated throughout with PTFE and mineral oil

Braided from Aramid staple fibre, impregnated with graphite and mineral oil

Diagonally braided from a proprietory yarn (Teadit EG-K) which consists of a core of Aramid fibers totally encased by gPTFE (PTFE/graphite), lubricated with silicone oil

Common Issues & Maintenance Tips

Aramid fiber has high strength and wear resistance, but excessive gland compression or insufficient lubrication may cause shaft or sleeve surface wear.

Maintenance Recommendations:

- Perform regular inspections during initial operation.

- Adjust gland pressure properly to avoid over-tightening or excessive looseness.

Custom Aramid Packing Manufacturer

We offer tailored aramid packing solutions to meet specific sealing requirements. Customization options include various types, special dimensions, spool preferences, and labeling、packaging to suit diverse application needs.