Ceramic Fiber Custom – Shaped Parts

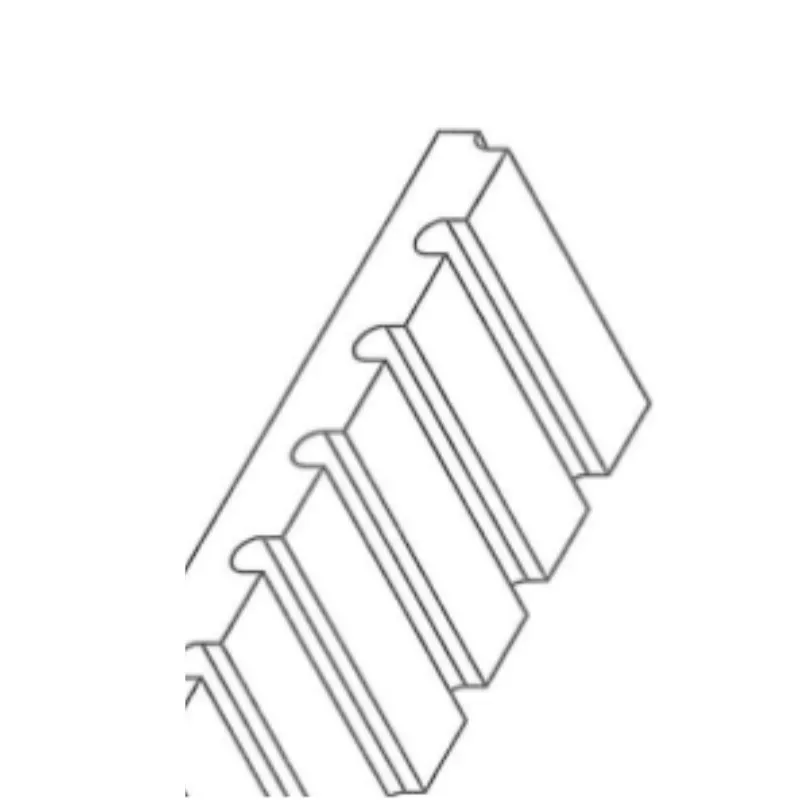

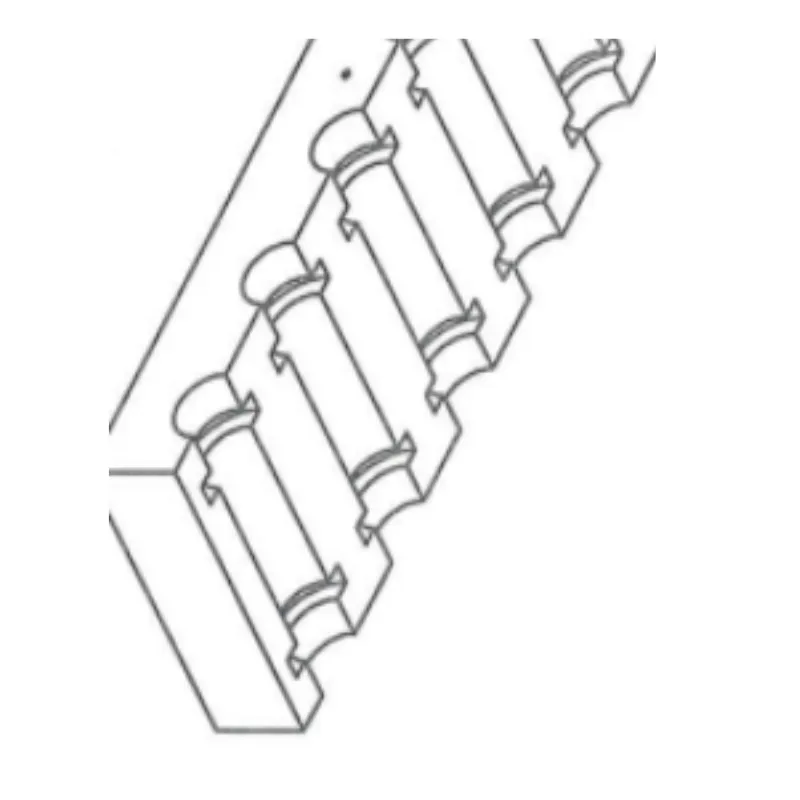

Ceramic fiber custom-shaped parts are high-temperature-resistant, lightweight, and thermally efficient components that can be precisely manufactured into complex configurations to meet specific industrial requirements. Custom ceramic fiber shapes are made from alumina-silica ceramic fibers and can withstand operating temperatures up to 1260°C. They offer excellent thermal insulation, low thermal conductivity, and resistance to thermal shock. These custom shapes can be manufactured into various complex geometries using vacuum forming and precision machining techniques to ensure tight dimensional tolerances and consistent performance. Common configurations include custom ceramic fiber tubes, ceramic fiber nozzles, ceramic fiber crucibles, ceramic fiber furnace liners, and ceramic fiber gaskets.

Key Features

High Temperature Resistance

Withstands continuous operation at temperatures up to 1000–1260°C, peak up to 1400°C.

Superior Insulation

Low thermal conductivity, improving energy efficiency and process control in high-temperature environments.

Lightweight & Strong

Easy to handle, transport,install without compromising strength,and install, reducing structural load and installation time.

Custom-Made Shapes

Can be manufactured to exact specifications, including intricate geometries and precise dimensional requirements.

Thermal Shock Resistance

Maintains structural integrity under rapid temperature changes, preventing cracking or degradation.

Good Chemical Stability

Resistant to most acids, alkalis, and corrosive atmospheres, ensuring long-term durability in harsh environments.

Eco-Friendly & Safe

Asbestos-free, odorless, and clean, ensuring a healthy and risk-free environment for all applications.

Industry

Application

Insulation shields and fireproof gaskets for pipelines, valves, burners, and reactors.

Used in ladle covers, casting outlets, and high-temperature seals.

Thermal protection in rockets, gas turbines, and nuclear facilities.

Fire door cores, insulation barriers, and cable sealing systems.

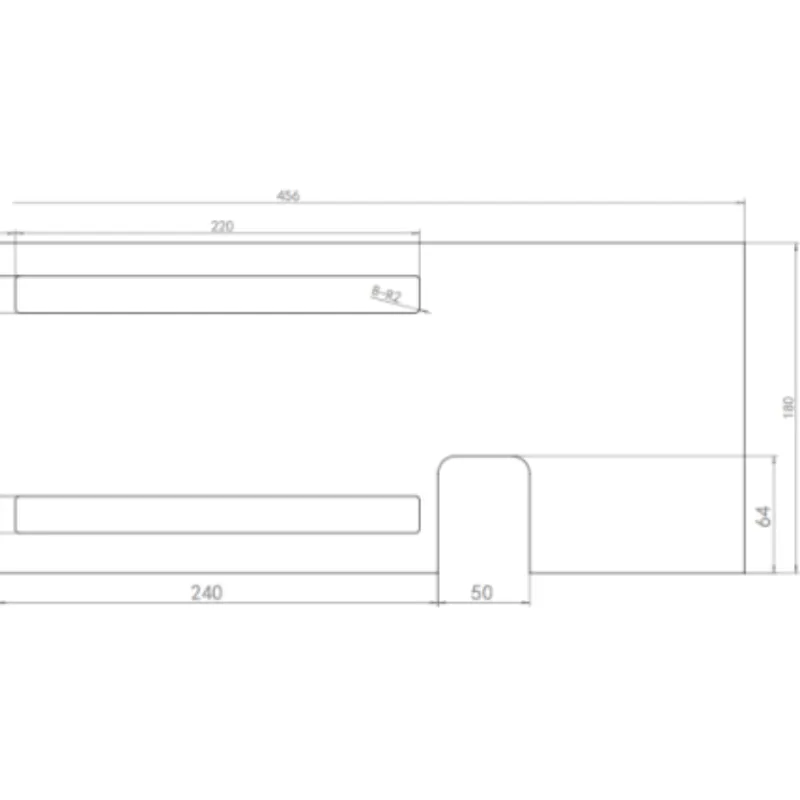

Specification Sheet

Product Code | MYTX-1260-46 / | MYTX-1260A-46 | MYTX-1350-46 | MYTX-1430-46 | MYTX-1600-46 |

Linear Shrinkage After Heat Soak (%) | 1000°C x 24h <3 | 1050°C x 24h <3 | 1200°C x 24h <3 | 1350°C x 24h <3 | 1500°C x 24h <3 |

Standard Specifications | Custom manufactured according to user-provided drawings. | ||||

Common Product Issues:

Surface Powdering

Minor surface dusting after use is normal. Avoid heavy impact.

Chemical Exposure

Keep away from strong acids and alkalis.

Proper Selection

Choose suitable density and temperature grade for long-term stability.

Custom Ceramic Fiber Custom-Shaped Parts Manufacturer

We offer customized ceramic fiber parts manufactured precisely to your drawings and specifications. Using high-temperature resistant materials and vacuum forming techniques, we produce complex shapes including tubes, nozzles, crucibles, and furnace liners for demanding industrial applications.